3 Reasons to Choose a Cascade Solution for your AGV

Posted by Cascade Corporation on Mon Feb 27 12:00:00 PST 2023

In the materials handling industry, expertise matters, and as companies continue to incorporate AGVs into their workflow, finding the right front end solution is a crucial investment decision. At Cascade, we’ve manufactured these AGV solutions for years, continually optimizing our technologies to provide the best, one-stop solution for your business.

But experience isn’t the only thing to consider when choosing AGV attachments, forks, masts and related technologies. That’s why, in addition to almost 80 years of manufacturing experience in the materials handling industry, Cascade can be your partner in an increasingly automated future. Here are three key reasons you should pair your AGV with a Cascade solution in your facility:

1. Electrify Your Productivity

Looking to get more out of your AGV? All-electric products from the Cascade Electrix™ product line represent the next generation of energy-efficient attachments. “Our Electric Sideshifter is 90% more energy efficient [than a hydraulic Sideshifter],” says Jesse Cramer, Corporate Manager for OEM Accounts in North America. “The efficiency of this Sideshifter is due in part to roller bearing technology, which provides smooth, low-effort movement of the unit. Additionally, the all-electric actuator system provides numerous other advantages, like variable speed and pinpoint accuracy in positioning, so the forks and carriage are always exactly where you need them for load handling.”

There are several key benefits to investing in electric attachments, including:

- Lower Total System Costs — with no hydraulics necessary, components like the hydraulic pump motor, oil reservoir, and hoses can be eliminated. By removing the hydraulic system from the equation, customers can reduce maintenance needs and eliminate contamination risks. To lower system costs and eliminate hydraulic components even further, our Electrix™ attachments can be combined with all-electric masts from Cascade subsidiary, Lift-Tek, providing a complete custom bundle solution for the front end of your AGV.

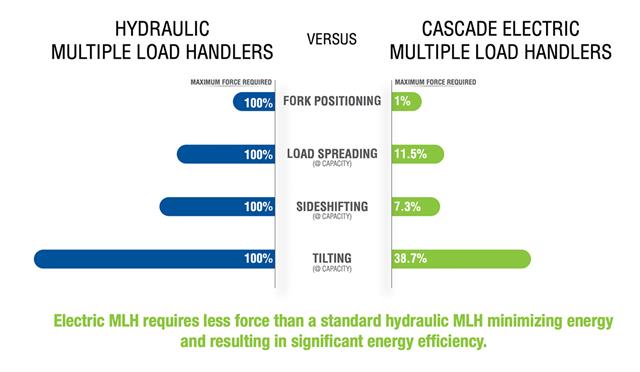

- Maximum Energy Efficiency — due to their superior energy efficiency, Electrix™ attachments, like our Electric Multiple Load Handler, are less taxing on your AGV, meaning less frequent charging needs and an overall increase in battery life.

- Data Analysis — valuable information, like actuator cycle counts and utilization rates, are easily transmitted to your AGV’s systems, where it can be used for predictive maintenance and workflow analysis. This data gives operations detailed knowledge of their attachment’s performance and can assist with process optimization.

2. ‘Glocal’ Support

The word ‘glocal’ stems from a combination of Cascade’s global resources and manufacturing presence with accessible, local support to ensure customer success.

Our “glocal” mindset is a foundational part of Cascade’s DNA that leverages our broad, global reach to serve local customers around the world with speed and precision. For example, our engineers recently produced several Tissue Roll Clamps for AGVs to handle large, delicate tissue rolls for a customer in Japan. “These clamps were designed at [Cascade] headquarters in Portland, Oregon, USA, with global manufacturing support and key components from Verona, Italy, and then shipped to the customer in Japan,” Clark Jordan, Vice President of Global Engineering, says. “And, if needed, our Cascade Japan team can quickly react to support and service requests on-site.”

Our global manufacturing presence complemented by local product support is a valuable resource during the transition to new technologies, like AGVs. With Cascade, you have a partner with you every step of the way to ensure our products fit your needs and function perfectly.

Need AGV attachment solutions for your small to medium-sized business?

An essential part of Cascade’s glocal identity is that no matter the scale of your operation, we can help. For years we’ve worked to adapt our forks and attachments to AGV projects of varying scales, from one machine to several hundred. With this experience, we can help businesses of any size transition to automation.

3. You need an Innovative Collaborator

“Cascade’s spirit of innovation is at the core of what we do, and for our customers, that means we never stop looking for opportunities to improve their materials handling.” - Clark Jordan, Vice President of Global Engineering at Cascade.

If you’re using AGVs, you’re not new to innovation and are most likely always looking for new ways to improve productivity. At Cascade, we are also driven by innovation; from extensive research and development to the latest manufacturing processes, innovation drives everything we do. This focus ensures that your Cascade attachment is both perfectly suited for today’s demands and prepared for tomorrow’s materials handling needs. Jordan explains, “With automated technologies undergoing a period of massive growth, it is important to look at the big picture and build foundational solutions that can easily evolve to meet future requirements.”

With automated technology moving goods faster than ever, Cascade has developed future-oriented attachment technologies to get the most out of your AGV now and for years to come. As Jordan describes, our products must have the versatility to meet (and exceed) modern AGV warehousing needs, which is why we build products for:

- Very Narrow Aisles (VNA) — if maximizing warehouse space with your AGVs is your top priority, Cascade designs attachments — like our Trilateral Head — that enable the forks to turn left or right 90 degrees and allow for navigation of narrow aisles with ease. Interested in utilizing double-deep pallet racking? Reachforks® extend the length of your AGV’s forks to take advantage of hard-to-reach areas, significantly bolstering your warehouse’s maximum capacity.

- Wide Industry Compatibility — Wherever AGVs go next, we will follow. Cascade has solutions for any materials handling industry, from Paper and Tissue to Logistics and White Goods. With smart solutions for all of these environments — like damage-reducing Sensor Forks and Multiple Load Handlers equipped with speedy RapidSync™ — your AGV will be the precision instrument you need to get the job done quickly and accurately.

- Specialized Environments — in many AGV workflows — especially e-commerce — the size and type of goods are changing constantly. Using specialized custom attachments from Cascade, you can meet these new demands while exceeding productivity expectations.

As Jordan explains, the overwhelming challenge in the materials handling industry today is that supply chains are operating at maximum capacity. “[That’s why] every second saved when moving products is critical, and every inefficiency solved is another step towards a more robust system.” With a materials handling solution from Cascade, your AGV can achieve its full potential by reaching peak efficiency.

Looking Toward the Future

“With the growth of AGVs, there are ever-expanding opportunities not only in warehousing and logistics operations but in virtually any application.” – Jesse Cramer

As AGVs continue adapting to different industries, Cascade will continue providing innovative solutions that maximize productivity. With installation support and sensor adaption for seamless integration into AGVs and unmatched after-sale services, Cascade is your partner for the long haul. Reach out to our team and see how we can limit your load positioning downtime and ensure your AGV’s optimum performance.